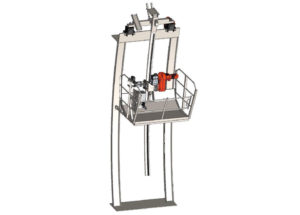

AGW1-P2

The AGW1-P2 Automatic Curved Plate Welder is an AGW which is also know as a (3 O’clock welder) has been developed to run on a rail for welding out of standard position girth seams on pressure vessels such as Spheres & Digesters.

The AGW Tank welders are a series of self-propelled Automatic Girth Welders (3 o’clock) welding equipment primarily developed for on-site erection of large storage tanks, silos, blast furnaces and similar cylindrical objects. It is available as a single-side version and a double-side version. Usually it is designed to travel on the top edge of the tank shell. As there are different ways of building tanks, one machine in the series is designed to travel on a rail which is temporarily fixed to the shell or on a stand-alone ring outside the shell.

The operator of each machine (if a full size version) rides in a cabin, where he supervises and controls the welding process with the control panel within easy reach. The cabin, whose floor level under the carriage is variable to suit the height of the plate, is built as a cage to give the operator(s) maximum safety and comfort. For weather protection the cage can be covered by curtains. The cabin of a double-side machine is equipped with ladders our an internal frame climbing system and a joining bridge at the top to facilitate for the operators to climb from one side to the other. The top and bridge has guard rails for the safety of the operators.

The girth welder is an automatic welding machine that straddles the tank plate and is used to complete a tanks circumferential weld joints. It’s typically used in a single or double sided configuration. In the single sided configuration one operator is required and welding on one side of the joint occurs. In the double sided configuration two operators are required and welding occurs simultaneously on both sides of the weld joint.

Girth Welders Features

- Fully integrated with LINCOLN electric submerged arc welding systems as standard (other welding systems on client’s request).

- Twin SEW motors drive system for reliable and steady weld travel .

- Inverter control for accurate speed adjustment.

- Fully adjustable weld head/ flux belt assembly.

- Precision machined slides ensure correct weld placement.

- Laser pointer to ensure correct tracking of the weld head in the circumferential seam.

- Powerful, reliable and efficient blower type vacuum flux recovery system.

- Flux heater option to keep flux away from moisture.

- Sequence control in “Auto mode” to allow one button startup.

- Integrated control with cooling for reliable operation in high temperature environment.

- Ergonomically positioned for the operator.

The line of tank equipment we supply includes items such as over 10 models of the Automatic Girth Welder (AGW), AGW-LNG, AGW-USA, AGW-LW Light Weight Automatic Girth Welder AGW-1, AGW-11, AGW1-P, AGW1-P2, AGW-stiffener welder, AGW-Mini, AGW-Sphere welder, AGW-Mig, which are also know as a (3 O’clock welder) Including an AGW built for tank Jacking (tank jack-Up) projects.

AGW1-EX is a single sided Automatic Girth Welder with an expandable and removable lower frame.

AGW2-EX is a double sided Automatic Girth Welder with an expandable and removable lower frame.

AGW-LW / Light weight Automatic Girth Welder has a open and lighter built frame with an expandable and removable lower frame.

AGW2-U tank girth welding machine can be used for standard bottom up or top down tank Jack-UP construction.

AGW1-U is a single sided Automatic Girth Welder that can be used for bottom up or top down tank jacking construction.

AGW-LNG are either a AGW1-LNG single sided or an AGW2-LNG which double sided are Automatic Girth Welder (AGW) / (3 O’clock welder) built to fit in the narrow space between the outer tank wall and the inner tank shell plate to perform low-temperature storage tank automatic girth welding.

AGW-P are a series of unmanned self-propelled Automatic Girth Welders designed to travel on a rail which is temporarily fixed to the shell plate.

AGW1-P2 Automatic Curved Plate Welder is an AGW which is also know as a (3 O’clock welder) has been developed to run on a rail for welding out of standard position girth seams on pressure vessels such as Spheres & Digesters.

AGW Stiffener welder is a new custom built automatic girth welder that has been built to run on top of the tank shell plate as other AGW’s however is has been designed with a wide range of vertical adjustment (top to bottom) not normally found in a AGW allowing this AGW to weld stiffeners onto the tank shell plate located in most elevations.

Automatic curved plate vertical welder

AVW-Multi pass curved plate welder:

Is a multiple pass Flux-cored vertical curved plate wire welding machine

AVW-multiple pass is a low heat input multiple pass automatic vertical welder set up for gas shielded .045/1.2mm FCAW / dual shield, specially designed for field construction of Sphere’s and Digesters.

Integrate with Standard BUGO or GULLCO welding carriage for mechanized gas shielded FCAW

Specifications:

- Adopt CO2 gas shielded or mixed gas shielded for dual shield FCAW welding process

- With the advantage of multiple pass low heat input for welding Spheres, Digesters and other pressure vessels that require multiple pass vertical welding

- Applicable for tank upward and inverse installation process

- Rack transverse automatic traveling

- Matched with A GULLCO or Bug-O automatic welding carriage and Lincoln LN-10 wire feeder for stable reliable performance

- Applicable plate thickness: 8-50mm

A list of automatic vertical welders we offer EGW-V, EGW-P, EGW-Jack-UP, EGW=Electro Gas Welder which is also know as a Vertical Up Welder (VUP), is a single pass Vertical-Up welder (VUP), AVW-multi pass, AVW-Jack-UP, AVW automatic vertical welder.

EGW-V: (Electrogas Welder) upward installation electrogas (arc) welding machine, for traditional storage tank welding;

EGW-V/D: (Electrogas Welder) inverse installation electrogas (arc) welding machine, for jacking construction of storage tank;

EGW-P: (Electrogas Welder) lightweight unmanned electrogas (arc) welding machine, mainly for power generation and wind tower welding;

VUP: Vertical Up Welder high heat input welding with Lincoln self shielded NR431 Inner shield wire;

AVW-Multi pass: low heat input multiple pass (FCAW / dual shield) arc welding machine, specially designed for field work construction of special steel brands (such as low-temperature steel and stainless steel)

Tank Welding LLC.

Is your complete source for Automatic Storage Tank Welding Machines. We specialize in custom built to order automatic tank welding machines for LNG & flat bottom tanks. We have multiple standard site proven Automatic Girth Welder designs (AGW) / 3 O’clock Welder designs. Single pass gas shielded EGW (Electrogas Welder), single pass self shielded VUP / vertical UP Welders & AVW / multiple pass Automatic Vert Welders, Automatic Vert Buggy, Shell Buggy, Tank Jacking Equipment and complete Tank Jacking systems, automatic curved plate welders for pressure vessel / sphere / digester welding. This line of equipment is built with your choice of USA made Lincoln or Miller welding systems. The AGW travel is powered by top of the line twin German engineered inverter controlled drive motors.

Explore all of our merchandise and contact us by phone or email. https://tankwelding.com/about-us/