AVW-Multi pass are multiple pass flux-cored wire welding machines

Link to Automatic Vert Welder information leaflet: AVW leaflet 10.22.2021

Automatic vert welder = AVW-multi pass

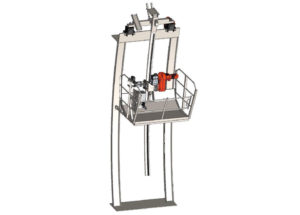

Is a low heat input multiple pass automatic vertical welder set up for gas shielded .045/1.2mm FCAW / dual shield, specially designed for field work construction of special steel brands (such as low-temperature 9%Ni steel and stainless steel) however is has an enclosed frame to block the wind for flat bottom carbon steel tank welding.

AVW MULTI-PASS VERTICAL WELDER: Are built for low temperature storage tank and bulk storage tank construction. It is integrated with Standard BUG-O or GULLCO welding carriage for mechanized FCAW. The frame has full aluminum panel wind shielding cabin efficiently bring operators and welding gears to vertical joints along tank shells and provide indoor conditions for high quality welding. Cabin is available in single or double sided and LNG model frames for double walled tanks with narrow inner/outer shell spacing.

Specifications:

- Adopt CO2 gas shielded or mixed gas shielded for dual shield FCAW welding process

- With the advantage of multiple pass low heat input welding for thin carbons steel tanks, cryogenic LNG storage tanks requiring multiple pass vertical welding

- Applicable for tank upward and inverse installation process

- Rack transverse automatic traveling

- Matched with A GULLCO or Bug-O automatic welding carriage and Lincoln LN-10 wire feeder for stable reliable performance

- Aluminum alloy track, magnet adsorption wallboard, not affected by the rack during the welding process

- Small welding carriage, lightweight, modular structure, flexible and convenient use

- Applicable tank diameter: ≥4.5m

- Applicable plate width: 1.6-3.2m (upward installation), 1.8-2.6m (inverse installation)

- Applicable plate thickness: 8-50mm

- Transverse traveling speed: 0~2700mm/min

Included:

- Wind resistant covered structure

- Control System

- Track

- Guide wheel mechanism

- Guardrail

- Vertical welding slide rail

- Traveling mechanism

- Welding torch water cooling system

- Bugo vertical welding carriage

Optional Accessories:

- Lifting Platform: Independent internal operator lift system to follow and control the welding process

- Welding fume vacuum system

- MPS (mobile power source, diesel welding machine)

Applications:

- Used for field construction of special steel brands (such as stainless steel and low-temperature steel 9% Ni, etc.)

- Used for thick plate welding in petroleum, chemical, blast furnace and shipbuilding industries

Automatic Vertical Curved Plate Welder

AVW-Multi pass automatic vertical curved plate welder is a multiple pass Flux-cored vertical wire welding machine.

AVW-multiple pass is a low heat input multiple pass automatic vertical welder set up for gas shielded .045/1.2mm FCAW / dual shield, specially designed for field construction of Sphere’s and Digesters.

Integrate with Standard BUGO or Gullco welding carriage for mechanized gas shielded FCAW

Specifications:

- Adopt CO2 gas shielded or mixed gas shielded for dual shield FCAW welding process

- With the advantage of multiple pass low heat input for welding Spheres, Digesters and other pressure vessels that require multiple pass vertical welding

- Applicable for tank upward and inverse installation process

- Rack transverse automatic traveling

- Matched with A GULLCO or Bug-O automatic welding carriage and Lincoln LN-10 wire feeder for stable reliable performance

- Applicable plate thickness: 8-50mm

A list of automatic vertical welders we offer EGW-V, EGW-P, EGW-Jack-UP, EGW=Electro Gas Welder which is also know as a Vertical Up Welder (VUP), is a single pass Vertical-Up welder (VUP), AVW-multi pass, AVW-Jack-UP, AVW automatic vertical welder.

EGW-V: (Electrogas Welder) upward installation electrogas (arc) welding machine, for traditional storage tank welding;

EGW-V/D: (Electrogas Welder) inverse installation electrogas (arc) welding machine, for jacking construction of storage tank;

EGW-P: (Electrogas Welder) lightweight unmanned electrogas (arc) welding machine, mainly for power generation and wind tower welding;

VUP: Vertical Up Welder high heat input welding with Lincoln self shielded NR431 Inner shield wire;

AVW-Multi pass: low heat input multiple pass (FCAW / dual shield) arc welding machine, specially designed for field work construction of special steel brands (such as low-temperature steel and stainless steel)

Tank Welding LLC.

Is your complete source for Automatic Storage Tank Welding Machines. We specialize in custom built to order automatic tank welding machines for LNG & flat bottom tanks. We have multiple standard site proven Automatic Girth Welder designs (AGW) / 3 O’clock Welder designs. Single pass gas shielded EGW (Electrogas Welder), single pass self shielded VUP / vertical UP Welders & AVW / multiple pass Automatic Vert Welders, Automatic Vert Buggy, Shell Buggy, Tank Jacking Equipment and complete Tank Jacking systems, automatic curved plate welders for pressure vessel / sphere / digester welding. This line of equipment is built with your choice of USA made Lincoln or Miller welding systems. The AGW travel is powered by top of the line twin German engineered inverter controlled drive motors.

Explore all of our merchandise and contact us by phone or email. https://tankwelding.com/about-us/