Electrogas Welder EGW-V & EGW-P are Electrogas Welding Machines EGW-V leaflet 10.27.2021

EGW-V: (Electrogas Welder) upward installation electrogas (arc) welding machine, for traditional storage tank welding; which is also know as a (AVW) automatic vert welder. EGW-V leaflet 10.27.2021

EGW-V/D: (Electrogas Welder) inverse installation electrogas (arc) welding machine, for jacking construction of storage tank; which is also know as a (AVW) automatic vert welder.

EGW-P: (Electrogas Welder) lightweight unmanned electrogas (arc) welding machine, mainly for power generation and wind tower welding; which is also know as a (AVW) automatic vert welder.

VUP: Vertical Up Welder high heat input welding with Lincoln self shielded NR431 Inner shield wire.

AVW-Multi pass: low heat input multiple pass (FCAW / dual shield) arc welding machine, specially designed for field work construction of special steel brands (such as low-temperature steel and stainless steel). AVW leaflet 10.22.2021

EGW (electrogas (arc) welding machines) which is also know as a (AVW) automatic vert welder are high efficient automatic welding equipment which achieves closed-loop control of carriage lifting via current feedback; Welding joint one-step forming thickness is 50mm, mainly used for thick plate single pass vertical seam welding in petroleum, chemical, blast furnace and ship building industries.

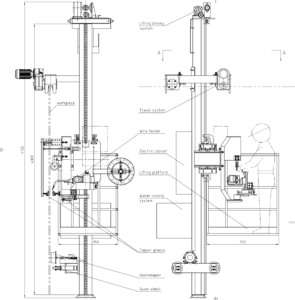

The EGW Single Pass Vertical Welder is a high productivity automatic vertical welding machine which uses real time closed-loop monitoring of the welding arc to accurately locate, control and adjust the welding head in the weld joint via arc current feedback and automatic carriage travel. This is used to complete single pass welds in material from 9 to 36mm thick but can also be used to complete thicker plate welds of up to 70mm when welding on both sides of the joint. This machine is used for vertical plate welding in the storage tank and many other applications.

A standard EGW-V electro gas welder can with a single or double sided frame (recommended) to house all the necessary components along with the operators for high deposition code quality vertical welding operation in any part of the storage tank.

Vertical Welders Features

- Adopts EGW (Electro Gas Welding) process for high speed carbon steel vertical welding with FCAW (Flux Cored Arc Welding) Process option for alloy steel vertical welding

- Lightweight travel carriage, self-propelled, weatherproof, fully contained operators cabin which allows safe access to the weld joint and easy set up and install

- Lightweight Aluminum track, quick mount electro magnets , easy assembly and disassembly;

- Real time monitoring of arc and automatic control of weld pool level, welding gun position and automatic adjustment of electrical stick out;

- Sequence control in “Auto mode” to allow one button startup.

- Onboard- self-contained continuous water cooling system

- Fully integrated with LINCOLN electric welding systems as standard (other welding systems on client’s request)

- SEW drive system for reliable and steady travel

- Different standard configurations for site erected Bottom Up and Top Down erected storage tanks or heavy wall cylindrical structures (eg. towers, blast furnace).

Specifications:

- Welding seam forced water cooling, one-step forming

- Automatic control of molten pool liquid level, automatic adjustment of welding wire extension length

- Aluminum track, magnet adsorption, easy assembly and disassembly

- Small carriage volume, light weight, module structure

Technical parameters:

- Electrogas(arc) welding: Solid wire with gas shielding or inner shield wire

- Applicable tank diameter: ≥4.5m

- Applicable plate width: 1.6-3.2m (upward installation) 1.8-2.6m (inverse installation, Tank Jack up)

- Applicable plate thickness: 8-50mm

- Automatic welding speed: 0-250mm/min

- Vehicle rapid traveling speed: 550mm/min

Please go to the below link to get an idea of how our EGW system operates welding on 1” plate, that is 108” long onsite in Australia.

- https://www.youtube.com/watch?v=lwSXkONvMU4

Vertical welder model we offer EGW-V, EGW-P, EGW-Jack-UP, EGW=Electro Gas Welder which is also know as a Vertical Up Welder (VUP), is a single pass Vertical-Up welder (VUP), AVW-multi pass, AVW-Jack-UP, AVW automatic vertical welder.

Electrogas welder | EGW – P are single pass unmanned vertical welding machines

EGW (electrogas (arc) welding machines) (Electrogas Welder) which is also know as a (AVW) automatic vert welder are high efficiency automatic welding equipment which achieve closed-loop control of carriage lifting via current feedback; Welding joint one-step forming thickness is 50mm, mainly used for thick plate single pass welding in petroleum, chemical, blast furnace and ship building industries.

Compact non operator carrying vertical welder that runs on shells for max flexibility

Eliminates limitation on plate width for conventional vertical welders

Suitable for general heavy wall vertical welding for tanks (repairs and construction), vertical cylindrical structures (piles, offshore jackets, chimneys etc) and vertical panels

Economical but sufficiently robust for heavy duty welding operation.

Specific models welding on inclined surface (eg. tank roof, inclined piles)

The EGW Single Pass Vertical Welder is a high productivity automatic vertical welding machine which uses real time closed-loop monitoring of the welding arc to accurately locate, control and adjust the welding head in the weld joint via arc current feedback and automatic carriage travel. This is used to complete single pass welds in material from 9 to 36mm thick but can also be used to complete thicker plate welds of up to 70mm when welding on both sides of the joint. This machine is used for vertical plate welding in the storage tank and many other applications.

Vertical Welders Features

- Adopts EGW (Electro Gas Welding) process for high speed carbon steel vertical welding with FCAW (Flux Cored Arc Welding) Process option for alloy steel vertical welding

- Lightweight travel carriage, self-propelled, weatherproof, fully contained operators cabin which allows safe access to the weld joint and easy set up and install

- Lightweight Aluminum track, quick mount electro magnets , easy assembly and disassembly;

- Real time monitoring of arc and automatic control of weld pool level, welding gun position and automatic adjustment of electrical stick out;

- Sequence control in “Auto mode” to allow one button startup.

- Onboard- self-contained continuous water cooling system

- Fully integrated with LINCOLN electric welding systems as standard (other welding systems on client’s request)

- SEW drive system for reliable and steady travel

- Different standard configurations for site erected Bottom Up and Top Down erected storage tanks or heavy wall cylindrical structures (eg. towers, blast furnace).

Applications:

- Adopt unmanned rack, small volume, light structure, convenient assembly, and disassembly, flexible use.

- Used in small and narrow space, mainly used in petrifaction, coal mine and electric power industries.

Vertical Up Welder, VUP, built as a column type Electrogas welder for welding carbon steel storage tanks in warm climates, AVW automatic vert welder

Developed for the Lincoln single pass Mechanical Vertishield process which usually uses the Lincoln NR431 Innershield wire. The All Time VUP operates at the same principle of electrogas welding as the All Time EGW, but it is made of a column & saddle structure instead of a fully enclosed frame design. Welder without the requirement of gas shielding, the All Time VUP is a simple & reliable option for high deposition tank vertical welding for wall thickness over 15mm.

This VUP Vertical Up Welder A.K.A (AVW automatic vert welder) is an open column type design for use with self shielded Lincoln NR431 inner shield wire for high heat input welding system in warm climates.

Tank Welding LLC.

Is your complete source for Automatic Storage Tank Welding Machines. We specialize in custom built to order automatic tank welding machines for LNG & flat bottom tanks. We have multiple standard site proven Automatic Girth Welder designs (AGW) / 3 O’clock Welder designs. Single pass gas shielded EGW (Electrogas Welder), single pass self shielded VUP / vertical UP Welders & AVW / multiple pass Automatic Vert Welders, Automatic Vert Buggy, Shell Buggy, Tank Jacking Equipment and complete Tank Jacking systems, automatic curved plate welders for pressure vessel / sphere / digester welding. This line of equipment is built with your choice of USA made Lincoln or Miller welding systems. The AGW travel is powered by top of the line twin German engineered inverter controlled drive motors.

Explore all of our merchandise and contact us by phone or email. https://tankwelding.com/about-us/